Stock administration is essential in enterprise—however it may be simpler mentioned than carried out. With out full visibility into what you will have and what individuals need, you may simply end up ordering an excessive amount of inventory—on the danger of by no means shifting it—or ordering too little, resulting in stockouts and annoyed clients who’ll begin trying elsewhere.

The answer? Good stock administration strategies. Let’s dive into 16 key strategies that may allow you to optimize inventory ranges, cut back carrying prices, keep away from lifeless inventory and provides clients what they need (when they need it).

Right here’s what we’ll cowl:

16 important stock administration strategies

1. Demand forecasting

Demand forecasting is the method of predicting future demand in your merchandise primarily based on historic information, developments and market evaluation. It’s a vital a part of working a enterprise—with out it, you’re mainly working your online business blindfolded.

With correct demand forecasting, you may be sure you have the correct amount of stock to satisfy demand—decreasing the chance of stockouts and annoyed clients—and keep away from heaps of undesirable items left to die in your storeroom or warehouse. Demand forecasting additionally facilitates higher planning, from extra correct budgeting to raised useful resource allocation and provide chain administration.

2. ABC evaluation

ABC evaluation is a listing administration approach that classifies stock into classes primarily based on its worth or significance to the enterprise’s total revenue.

Class A: most beneficial gadgets, often primarily based on gross sales quantity, revenue margin or price to accumulate. Class A gadgets usually make up a small share of complete stock however convey within the majority of income. This stuff want shut monitoring and tight stock management.

Class B: essential gadgets, however much less essential than Class A gadgets on account of decrease profitability or gross sales quantity. This stuff require consideration and monitoring, however not at Class A ranges.

Class C: gadgets with the least affect on gross sales and lowest revenue margins. This stuff usually account for 50% or extra of complete stock however contribute the least to income, thus requiring minimal oversight.

By prioritizing stock that has the most important affect on their backside line, companies can apply the suitable controls and sources required to handle it.

3. Security inventory stock

Security inventory is the additional inventory you order past your forecasted demand. It’s successfully a buffer between you and stockouts, accounting for uncertainties like unexpectedly excessive demand, provider delays or non permanent outages.

So how a lot security inventory must you maintain readily available? TL;DR, there are a variety of formulation that retailers and stock managers use to calculate security inventory ranges, however right here’s the fundamental components:

Security inventory = (most every day gross sales x most lead time) – (common every day gross sales x common lead time)

To make use of this components, first verify your gross sales over a given time period—say, a month. Then collect the next information for every SKU:

common every day gross sales

most every day gross sales

common lead time

most lead time

To maintain it easy, let’s say your online business solely sells one SKU—a candle. On common, you promote 50 candles a day, however on someday of that month, you bought 100 candles. And also you often obtain new shipments out of your provider inside 4 days of submitting a purchase order order. Nonetheless, it’s taken so long as 12 days to get your order that month.

Right here’s what that offers you:

common every day gross sales = 50

most every day gross sales = 100

common lead time = 4 days

most lead time = 12 days

Now you may plug in your numbers and begin crunching:

Security inventory = (100 x 12) – (50 x 4)

Security inventory = 1,200 – 200

Security inventory = 1,000

Utilizing this components, you’d maintain 1,000 further candles readily available always.

4. Reorder factors

Reorder factors are mainly the bottom acceptable stage of stock earlier than you’ll want to reorder, taking into consideration an merchandise’s gross sales quantity and lead time. Any decrease than that, and also you’re within the hazard zone for stockouts and sad clients.

So, how do you determine reorder factors in your stock? Properly, there are three key variables to think about for a primary reorder level calculation: common every day gross sales, lead time and security inventory. The components is:

Reorder level = (common every day gross sales x supply lead time) + security inventory

Fortunately, we lined find out how to calculate security inventory within the part above. So utilizing the identical instance as above, the reorder level calculation in your candle retailer—which inexplicably sells just one candle—would appear like this:

Reorder level = (50 x 4) + 1,000

Reorder level = 200 + 1,000

Reorder level = 1,200

Study extra about calculating reorder factors.

5. PAR ranges

Periodic computerized replenishment (PAR) is a listing administration approach that includes setting a most and minimal amount for every stock merchandise. These maximums and minimums are known as PAR ranges.

When stock for a product approaches the minimal PAR stage, the merchandise needs to be reordered. Utilizing stock administration software program like Lightspeed, you may set reorder factors that can routinely set off a reorder to assist convey your stock again as much as PAR.

Right here’s the way it works:

Out of your product catalog, choose the product you need to create a reorder level for.

Choose ‘Edit product’, then scroll all the way down to the ‘Stock’ part.

Below ‘Stock ranges’, enter the merchandise’s reorder level within the ‘Reorder level’ subject (seize the reorder level components within the part above).

Set the default reorder amount within the ‘Reorder amount’ subject.

This computerized course of helps be sure that inventory is replenished earlier than it runs out, stopping stockouts and making certain easy operations.

6. Simply-in-time (JIT) stock

The just-in-time (JIT) stock administration methodology focuses on preserving as little stock readily available as potential. So as an alternative of ordering stock or provides upfront to be prepared to satisfy forecasted demand, JIT includes ordering small shipments to switch stock as you forecast and fulfill orders.

Sounds nice, proper? However there’s a catch—you’ll want to have secure demand and very dependable suppliers. Even then, chances are you’ll be at the next danger of stockouts and missed gross sales on account of provide chain disruptions.

7. Dropshipping

Stock administration doesn’t get simpler than dropshipping, primarily since you don’t truly maintain any stock readily available. Dropshippers work with a 3rd occasion provider who ships the order on to the client when an order is positioned. Right here’s the way it works:

A buyer locations an order in your on-line retailer.

You ahead the order to your provider and pay the wholesale value.

The provider prepares and ships the product on to the client.

The client receives the product, and you retain the revenue from the sale.

Remember the fact that you—and never the provider—are accountable for buyer aftercare, together with dealing with any complaints or buyer refunds.

8. Cross-docking

Cross-docking is a way for managing stock that basically skips the storage a part of stock. As an alternative of shifting stock into the warehouse to be shipped out later, product strikes instantly from the receiving dock to the delivery doc for instant loading onto outbound vans. Right here’s how that works:

Items are acquired from inbound vans.

Items are unloaded, sorted and reorganized.

Items transfer from the receiving dock to the delivery doc.

Items are instantly loaded onto outbound vans for cargo.

Cross-docking can velocity up supply occasions, reduce the necessity for warehouse house and cut back stock dealing with and holding prices. Nonetheless, it requires exact coordination with suppliers and might not be acceptable for companies with low product turnover.

9. Stock administration software program

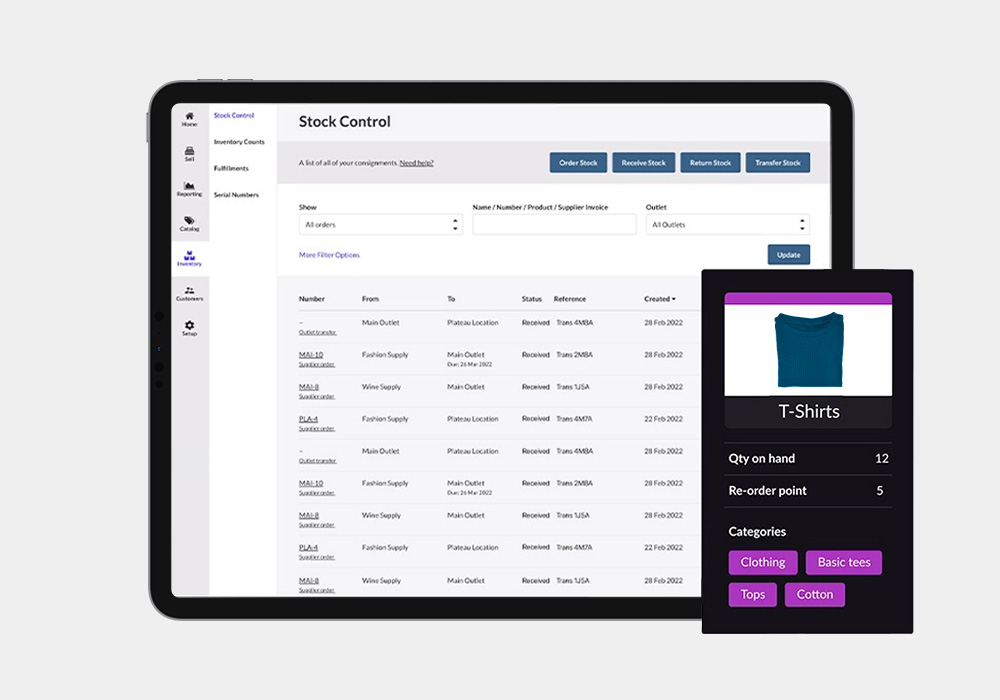

Stock administration software program helps retailers observe stock, precisely forecast demand, streamline processes and in the end cut back prices.

The very best stock administration software program in your retail enterprise will depend on your particular operations and desires. Listed here are some key options to search for when selecting stock administration software program:

Actual-time updates: routinely updates stock ranges as merchandise are bought or acquired, making certain correct inventory counts, so you may forestall stockouts and overstocking with up-to-date insights into what you will have readily available.

Automated reordering: routinely provides merchandise to your low inventory report after they attain your pre-set “hazard zone” and auto-populates a reorder for you, so you may be sure you’ve bought sufficient of what you want, whenever you want it.

Multi-location stock administration: connects all of your areas and gross sales channels, whether or not they’re on website, on-line or in warehouses or distribution facilities, permitting you to trace and handle all of your stock from a single platform.

Insights & reporting: superior insights and detailed reporting into gross sales developments, stock ranges and product efficiency, empowering you to make knowledgeable selections about reordering, promos and enterprise technique.

As your online business grows, a complicated, versatile stock administration system like Lightspeed can develop with you. Study extra.

10. FIFO and LIFO

First in, first out (FIFO) and final in, first out (LIFO) are two stock administration strategies that govern which stock is bought first. With FIFO, the oldest stock gadgets are bought or used first, and it’s primarily used to handle perishable meals like meals or prescribed drugs, which must be bought earlier than they expire.

With LIFO, you promote the latest business first. Why? As a result of when costs are rising, utilizing the dearer, just lately acquired inventory to calculate your price of products bought (COGS) can provide you a extra correct image of your organization’s monetary well being. It additionally lowers your income (on paper, anyway), which can lead to important tax financial savings, however solely in the USA.

11. Consignment stock

Consignment stock is a provide chain mannequin through which a retailer (consignee) agrees to promote a provider’s product, however the provider (consignor) owns the product till it’s bought to a buyer. As a result of the retailer doesn’t truly purchase the stock till it sells the merchandise, it could actually return no matter doesn’t promote to the provider.

This mannequin provides important benefits to each events, together with higher market attain for suppliers and decrease monetary danger for retailers.

Efficiently promoting inventory on consignment will depend on a stable consignment settlement. That is the contract between the consignor and consignee that clearly outlines the phrases of the settlement, together with fee phrases, period and the rights and obligations of every occasion. Mainly, it clearly spells out who does what and who pays for what.

12. Financial order amount (EOQ)

Financial order amount (EOQ) is a calculation firms use to determine the optimum order amount for a product that can meet demand whereas minimizing complete stock prices—from ordering prices (like delivery and dealing with) to holding prices (like storage and insurance coverage).

There are a number of variations of the components used to calculate EOQ, however right here’s one of the crucial fashionable:

EOQ = √ [ (2 x order cost x annual demand in units) / holding costs]

To calculate a product’s EOQ with this components, you’ll want a primary understanding of algebra and the next variables:

Annual demand in items. Examine your historic order and gross sales information to find out what number of items you promote per yr.

Order price = delivery and dealing with prices per order

Holding prices (per yr, per unit) = complete price of holding unsold items (e.g. warehousing charges, insurance coverage, and many others.)

If it’s been some time because you’ve needed to discover the sq. root of one thing, right here’s a free sq. root calculator that may do it for you.

13. Perpetual stock administration

Perpetual stock makes use of software program like level of sale (POS) programs and scanners to replace stock counts routinely with each sale, buy or return. This stock administration approach gives correct inventory counts in actual time, serving to retailers enhance stock accuracy, demand forecasting and decision-making.

In a perpetual stock system, each product is assigned a monitoring code, resembling a barcode or RFID code. These are the fundamental steps to implement perpetual stock monitoring in your warehouse or retail retailer:

Labeling: connect a singular barcode or RFID tag to every product in your stock. This tag accommodates essential details about the merchandise, together with its amount and site.

Scanning: everytime you promote, obtain or transfer an merchandise, scan its tag. This updates your stock depend in real-time, so that you all the time know what’s in inventory and the place to search out it.

Stock administration software program: subtle stock administration software program updates inventory ranges routinely as transactions happen, lets you view and observe stock throughout a number of areas and gross sales channels, and allows you to handle your whole operation from a single unified platform.

Analyzing key metrics: use superior insights into your key efficiency metrics to optimize stock, spot developments and make knowledgeable choices about reordering and promotions.

14. Minimal order amount (MOQ)

Minimal Order Amount (MOQ) refers back to the minimal variety of items that you need to order out of your provider at anybody time. These are set by the provider to make sure they will cowl their manufacturing prices and make a revenue on the sale. MOQs could be irritating for retailers who could really feel “pressured” to order greater than they want, however on the finish of the day, no one bought into this enterprise to lose cash.

In case your provider has carried out an MOQ for a number of of the merchandise you need to order, use demand forecasting to find out in the event you’ll want not less than that variety of items. If the distinction between your perfect order amount and your provider’s MOQ is negligible, then it most likely is sensible to maneuver ahead with the order. If not, you’ll have to search for a unique provider, or attempt to negotiate a compromise along with your desired provider.

When you’re a retailer who sells wholesale to different retailers, you might need to set your personal MOQs. Whereas there’s no set components for calculating MOQs, you’ll need to think about the next variables:

Demand: use historic information to forecast demand. Take into account components like seasonality, lead time and competitors.

Holding prices: in any other case often called stock carrying prices, holding prices could embrace warehousing charges, insurance coverage charges, power prices, and many others.

Break-even level: what number of items you’ll want to promote to cowl your prices. Be sure you take all of your overhead prices into consideration, from the worth of supplies to labor and storage prices.

15. Bulk delivery

Bulk delivery includes shopping for and transporting massive portions of merchandise without delay. This reduces per-unit transportation prices—and may usually get you a reduction out of your provider—as a result of the overall delivery price is unfold throughout a bigger variety of gadgets.

That mentioned, bulk delivery can even lead to overstocking, overcrowding, product injury, and longer dealing with occasions. Companies additionally want satisfactory cupboard space and dealing with tools to handle these massive shipments effectively, the prices of which can surpass what you’re saving in transportation prices.

16. Batch monitoring

Batch monitoring refers to a listing administration approach that makes it simpler for companies to watch and hint teams of merchandise as they transfer via the availability chain, from manufacturing all the best way to clients.

It really works by grouping collectively merchandise with related properties inside a bigger group of merchandise. These product teams are assigned a singular batch or lot quantity on the manufacturing stage. These batch/lot numbers retailer essential product particulars, resembling manufacturing date, supplies used, expiration dates, historical past of high quality assurance checks, and many others.

As merchandise transfer via the availability chain, their batch quantity is scanned and logged at every stage. If high quality points come up or a product recall is required, batch monitoring makes it a lot simpler to determine the supply of the issue, find and pull the affected merchandise and determine every other merchandise that might have been affected.

Backside line

Efficient stock administration is non-negotiable in at present’s retail panorama, and helps retailers guarantee they’ve the correct merchandise in inventory on the proper time, minimizing misplaced gross sales and decreasing extra stock.

By implementing strategies like FIFO, automated reorder factors, security inventory, and perpetual stock administration—amongst others—you may enhance your total effectivity, unlock capital, cut back pointless prices and increase buyer satisfaction.

So, in case your present stock administration methodology is supplying you with a headache, it is likely to be time to take a number of of those strategies for a spin.

Wish to find out how instruments like Lightspeed level of sale (POS) and stock administration software program may also help you save a ton of time on stock administration and achieve higher accuracy and management? Guide a demo with considered one of our POS specialists at present.

FAQs

What’s the mostly used stock administration methodology?

FIFO (First In, First Out) is without doubt one of the most generally used stock administration strategies. It ensures that older inventory is bought first, serving to companies handle stock turnover, keep away from stockpiling outdated merchandise and keep an environment friendly stream of merchandise.

What’s the greatest stock methodology for a small enterprise?

For small companies, the First-In, First-Out (FIFO) methodology is commonly the perfect stock administration alternative. It’s easy to make use of, making certain older inventory sells first, which helps keep product freshness and helps forestall getting caught with tons of outdated stock. Pairing FIFO with a listing administration software program that tracks gross sales each in-store and on-line may also help small companies keep organized, automate reorder alerts and handle inventory ranges with ease and accuracy.

How do you overcome poor stock administration?

To beat poor stock administration, use stock administration software program for real-time monitoring, arrange automated reorder alerts and implement common inventory audits. These strategies of stock administration can vastly improve accuracy and effectivity.