Environment friendly warehouse inventory administration, guided by the proper warehouse effectivity ideas, could make or break your small business. With out it, you threat falling behind; with it, you acquire real-time management and the ability to outpace your competitors.

Poor inventory administration can ripple throughout your small business operations, resulting in vital monetary losses, operational inefficiencies and maybe most damagingly, buyer dissatisfaction. When objects are mismanaged, out-of-stock or delayed, it not solely impacts gross sales but additionally erodes belief in your model. One McKinsey research discovered that solely 13% of buyers are prepared to attend so that you can restock—they’re much more prone to change manufacturers as a substitute.

The reply? A sturdy warehouse inventory administration system that may rework these challenges into alternatives for progress and reliability.

On this weblog, we’ll cowl:

The Worth of a Unified Funds and POS Resolution

An in-depth take a look at how a streamlined platform for fee processing can rework the way in which you use your small business, particularly in comparison with legacy methods and patchwork options.

What’s warehouse administration?

Warehouse administration is a system for dealing with all facets of operations inside a warehouse or distribution heart. Its objective is to streamline processes and guarantee environment friendly workflow.

At its core, warehouse administration includes managing and optimizing a variety of features, from stock management to order success, every enjoying an important function within the total enterprise technique.

A warehouse administration system can have instruments and processes for:

Receiving and putaway: the primary steps within the warehouse cycle involving the acceptance of incoming items and their appropriate placement within the warehouse. Environment friendly processes listed below are important to stop bottlenecks in a while

Stock management: sustaining correct information of all objects coming into and leaving the warehouse, guaranteeing that inventory ranges are adequate to satisfy demand with out overstocking, which might tie up capital unnecessarily

Storage optimization: the strategic placement of products inside a warehouse to maximise area utilization and decrease retrieval time

Order success: guaranteeing that clients obtain their merchandise promptly and precisely, which is important for sustaining buyer satisfaction and loyalty

Expertise integration: methods like Warehouse Administration Programs (WMS), level of sale (POS) software program, barcode scanners and RFID know-how to reinforce accuracy and velocity up operations

Labor administration: scheduling and deployment of warehouse workers to keep up productiveness and meet operational calls for

Security and compliance: guaranteeing that operations adhere to authorized requirements and work practices to maintain workers protected and keep away from penalties

Contemplate a furnishings retail enterprise: environment friendly warehouse administration ensures {that a} fashionable couch mannequin is at all times in inventory, saved safely in a method that forestalls harm and will be simply picked and shipped when an order is positioned on-line. This impacts not simply logistics but additionally gross sales, customer support and in the end model status.

Why is warehouse stock administration necessary?

Warehouse stock administration helps companies optimize operations, cut back prices and improve buyer satisfaction—and extra.

Diminished prices

Do you know US retailers are sitting on $740 billion in unsold items? That’s a variety of caught stock driving up prices—prices to retailer, handle and monitor merchandise that aren’t promoting.

Correct stock administration helps cut back carrying prices, together with storage charges, insurance coverage and potential spoilage, by guaranteeing that inventory ranges are excellent—not too excessive and never too low. This steadiness minimizes waste and reduces the monetary burden on the corporate.

Elevated productiveness

Efficient stock administration ensures that inventory ranges are precisely recorded, which prevents overordering and understocking.

This accuracy helps streamline the choosing and packing processes, thereby boosting productiveness. Employees spend much less time trying to find objects or coping with inventory discrepancies.

Improved accuracy

Warehouse stock administration methods usually make the most of applied sciences like barcode scanning and RFID monitoring to make sure each merchandise is precisely logged because it strikes out and in of the warehouse. This precision eliminates errors in inventory counts, lowering the cases of mispicks and misships that may happen resulting from incorrect stock knowledge.

Sooner delivery

Environment friendly warehouse stock administration streamlines the order success course of by organizing inventory in a method that optimizes choosing and packing paths.

For instance, with Lightspeed, you may file and examine the place your merchandise are saved on the Aisle, Bay, Shelf and Bin degree per outlet proper in your retail level of sale. Meaning much less searching and trying to find warehouse workers, dashing up the delivery course of.

Actual-time stock updates additionally assist in promptly processing orders and guaranteeing that objects can be found and able to ship, thus minimizing delays and rising total delivery effectivity.

Elevated buyer satisfaction

By managing warehouse stock successfully, companies can make sure that merchandise can be found when clients want them, thus avoiding backorders and potential gross sales losses.

7 most competent practices for environment friendly stock administration

Prioritize your stock

Use identification markers

Carry out common audits

Deal with inventory successfully

File your gross sales

Streamline your stock administration plan with outlined roles

Use stock administration software program

1. Prioritize your stock

Classify stock utilizing strategies like ABC evaluation, which segments objects based mostly on their significance and gross sales quantity.

ABC stock evaluation is a way that divides stock into three classes (A, B, and C) to find out which objects require essentially the most consideration and sources.

Class A contains objects which can be essentially the most helpful, usually making up a small proportion of stock however accounting for almost all of the income. These require frequent evaluate and tight stock management

Class B objects are of average worth, normally constituting a bigger proportion of stock than A objects however much less important to income. They profit from common monitoring however much less intensive administration

Class C objects are the least helpful, usually making up the majority of stock numbers however contributing the least to income; they require minimal oversight

This categorization helps in focusing efforts and sources on essentially the most financially impactful objects, thereby optimizing stock ranges and lowering carrying prices related to much less essential objects.

2. Use identification markings

Implement a labeling system with barcodes or RFID tags to trace every merchandise effectively. This aids in rapidly finding items inside the warehouse and hastens the choosing course of.

For instance, a furnishings warehouse would possibly use distinct markings to distinguish between similar-looking objects like chairs and tables of various fashions or colours.

To get essentially the most out of your identification markings:

Standardize labeling practices: develop a uniform labeling system that features clear, constant pointers on the place and the way labels ought to be utilized to various kinds of merchandise

Incorporate descriptive info: labels ought to embody not only a distinctive identifier but additionally important info reminiscent of product kind, measurement, shade and dealing with directions

Make the most of shade coding: add shade codes to labels to additional improve the velocity and accuracy of the choosing course of. For instance, totally different colours may signify totally different product classes or precedence ranges

Leverage know-how: make use of superior scanning methods and cellular gadgets, like Lightspeed Scanner, to learn barcodes and tags. These applied sciences velocity up the verification and monitoring of things by way of real-time updates to the stock administration system

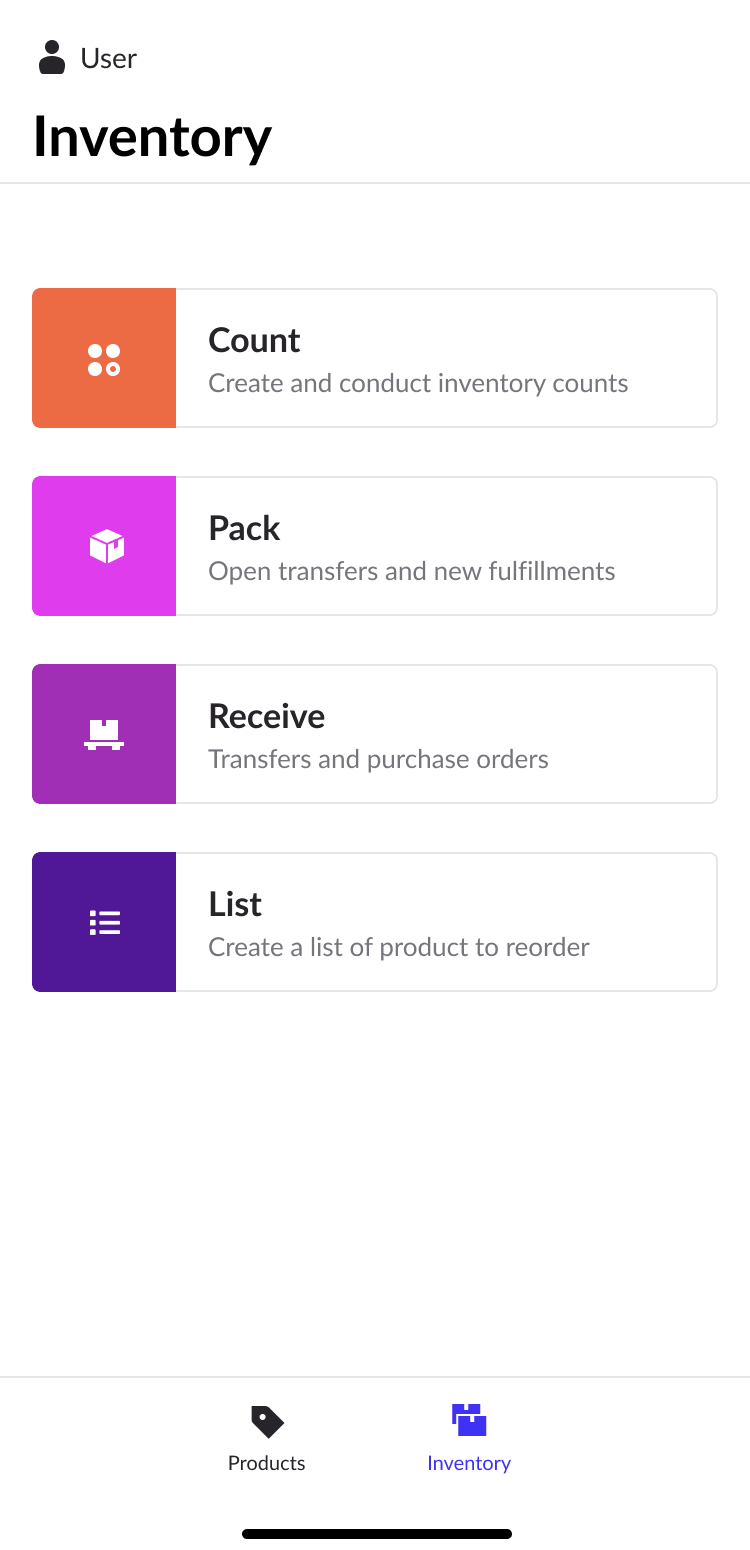

The Lightspeed Scanner app interface

3. Carry out common audits

Frequently scheduled audits, reminiscent of cycle counts, assist preserve stock accuracy by verifying your bodily inventory in opposition to the recorded stock. This follow catches discrepancies and points early, lowering the chance of stockouts or overstock conditions.

Conducting audits quarterly and even month-to-month, relying on the dimensions of the operation, can considerably improve stock management. To set your audits up for fulfillment:

Set clear targets: earlier than scheduling an audit, outline what you purpose to attain, whether or not it’s verifying accuracy, assessing compliance with storage procedures, or figuring out out of date stock

Use a rotating schedule: implement a rotating schedule for cycle counts so that every one stock is audited over a set interval. This method prevents the disruption of every day operations and spreads the workload evenly throughout the 12 months

Practice your group: make sure that workers conducting the audits are well-trained in auditing procedures and perceive learn how to use any related know-how or tools

Leverage know-how… once more: make the most of stock administration software program and scanning know-how (like Scanner) to streamline the audit course of

Overview and act on findings: after every audit, evaluate the findings and take applicable actions to handle any recognized points. This might contain adjusting stock ranges, updating information or revising storage practices

4. Deal with inventory successfully

Develop protocols for dealing with inventory that decrease harm and loss, reminiscent of correct stacking strategies and the usage of appropriate dealing with tools.

Be sure to tailor your protocols to the kind of inventory you’re carrying. Some examples embody:

Electronics warehouse: use anti-static flooring and instruments to stop harm.

Attire and textiles warehouse: make the most of garment racks and coated bins to guard objects from mud and filth. Be certain that dealing with workers use gloves to stop oils or filth from contaminating the materials

Furnishings warehouse: equip with dollies, furnishings pads and straps to guard furnishings throughout motion. Stack lighter objects on heavier, extra secure objects and keep away from stacking objects too excessive to stop tipping

Chemical warehouse: implement spill containment measures and use corrosion-resistant shelving. Employees ought to put on applicable security gear, together with gloves and goggles, and supplies ought to be saved in response to compatibility

Heavy equipment warehouse: make the most of cranes, forklifts and pallet jacks which can be rated for heavy hundreds. Be certain that aisles are extensive sufficient to accommodate giant tools motion and that flooring load limits are strictly adhered to

5. File your gross sales

Conserving correct information of gross sales helps monitor stock ranges and predict future demand. This knowledge is essential for planning purchases and may also help keep away from extra stock that ties up capital.

Using level of sale methods that replace stock in actual time as gross sales happen offers a transparent image of inventory ranges at any given second.

6. Streamline your stock administration plan with outlined roles

Develop a transparent, structured plan that outlines processes for buying, storing and promoting stock. This plan ought to embody outlined roles and obligations on your group, like:

Stock supervisor: oversees all facets of stock management; coordinates buying, monitoring and replenishment actions; ensures accuracy in stock counts and information

Buying officer: liable for procuring inventory based mostly on the demand forecasts and stock ranges; negotiates with suppliers to safe the very best costs and phrases

Warehouse supervisor: manages the day-to-day operations inside the warehouse, together with staffing, scheduling and guaranteeing adherence to security protocols; oversees the receiving, storing, and delivery processes

Inventory handlers: carry out duties associated to the bodily dealing with of products together with receiving, storing, choosing, and packing; guarantee correct dealing with strategies to reduce harm

High quality management inspector: checks incoming and outgoing merchandise for high quality and compliance with specs; manages returns of faulty objects to suppliers

Knowledge analyst: tracks stock knowledge and analyzes patterns in inventory motion and utilization; offers studies that assist in making knowledgeable choices about inventory administration

7. Use stock administration software program

Adopting subtle stock administration software program can automate many facets of stock management, from ordering and monitoring inventory to forecasting demand.

This software program can combine with different methods like CRM and ERP, offering a complete view of enterprise operations and enhancing decision-making.

For instance, software program that syncs stock knowledge throughout on-line and bodily shops can guarantee constant buyer experiences.

Choosing the proper warehouse inventory administration system

Choosing the proper Warehouse Inventory Administration System (WMS) is essential for optimizing warehouse operations, enhancing accuracy, and rising effectivity.

Kinds of warehouse administration methods

Primary WMS

These methods deal with elementary operations reminiscent of stock monitoring, easy choosing and packing processes and fundamental reporting. They are perfect for smaller operations or these with easy wants.

Superior WMS

These provide extra complicated options like batch choosing, cross-docking, labor administration and detailed analytics. They’re appropriate for bigger warehouses with extra complicated operations.

Built-in WMS

Typically half of a bigger enterprise useful resource planning (ERP) system, these are designed for corporations needing a complete answer that covers all facets of enterprise operations past simply warehouse administration.

Cloud-based WMS

These methods are hosted on the cloud, providing scalability, distant accessibility and decrease upfront prices. They’re changing into more and more fashionable resulting from their ease of integration with different cloud-based purposes.

Key options to search for in a WMS

Actual-time stock monitoring: important for sustaining correct inventory ranges and offering visibility throughout all channels

Scalability: the system ought to develop with your small business, accommodating elevated quantity with out efficiency points

Integration capabilities: WMS ought to simply combine with different methods reminiscent of accounting, buyer relationship administration (CRM) and buying software program, in addition to your POS

Person-friendly interface: ensures that your group can make the most of the system successfully with minimal coaching

Assist and updates: search for a vendor that gives robust buyer assist and common updates to maintain the system safe and useful

Why Lightspeed is a wonderful alternative on your warehouse

Lightspeed presents a complicated but user-friendly level of sale tailor-made to trendy retail and wholesale calls for. It really works alongside your ERP system, like NetSuite, to assist deal with warehouse and entrance of home duties.

Our robust concentrate on integration and real-time knowledge processing units us aside. Whether or not you’re working a single warehouse or a number of distribution facilities, Lightspeed’s POS seamlessly integrates with different enterprise instruments, offering a unified view of gross sales, stock and buyer knowledge.

Lightspeed encompasses a sturdy analytics instrument that helps companies forecast demand, optimize stock ranges and cut back waste. The cloud-based nature of Lightspeed ensures that it’s scalable, cost-effective and at all times up-to-date with the most recent options and safety measures.

Backside Line

Efficient warehouse inventory administration is greater than a logistical necessity—it’s integral to your small business’s success, immediately impacting every thing from monetary well being to buyer satisfaction.

By implementing a strong warehouse inventory administration system, you change potential challenges into alternatives for progress, reliability and buyer loyalty.

Whether or not you’re managing a sprawling furnishings warehouse or a high-volume electronics distribution heart, the insights and practices shared right here can information you in direction of extra streamlined, environment friendly and error-free operations. And Lightspeed’s stock administration software program could possibly be the lacking piece to convey all of it collectively—why not watch a demo and see what we’re all about?

Continuously requested questions on warehouse administration

What’s a warehouse administration course of?

A warehouse administration course of encompasses the assorted methods and strategies employed to run warehouse operations easily and effectively. This contains dealing with all facets of the warehouse’s performance from the time items or supplies enter the warehouse till they’re moved out.

The method includes:

Managing bodily warehouse infrastructure

Dealing with stock, each receiving and packing

Guaranteeing the proper processing and success of orders

Overseeing workforce administration

Optimizing layouts and processes for storage and retrieval effectivity

Implementing know-how options like Warehouse Administration Programs (WMS) to streamline operations

Efficient warehouse administration goals to reduce prices and operational delays whereas maximizing productiveness and accuracy so as success.

What are the fundamental warehouse operations?

Primary warehouse operations seek advice from the foundational duties required to handle the storage and motion of products inside a warehouse setting successfully. These operations usually embody:

Receiving: the method of accepting and checking shipments as they arrive, guaranteeing the products match the acquisition orders, and are free from harm

Putaway: after items are acquired, they’re moved to their particular storage areas. Environment friendly putaway processes assist in sustaining order and ease of entry within the warehouse

Storage: the safekeeping of products in an organized method to facilitate quick access and environment friendly area utilization. Correct storage prevents harm and lack of merchandise

Selecting: the retrieval of products from their storage areas in response to particular buyer orders. This step is important because it immediately impacts order accuracy

Packing: packaging objects appropriately as soon as picked to organize them for cargo to make sure they attain clients in good situation

Delivery: dispatching of the packed objects to the shopper, together with arranging for transport and documentation crucial for the products’ supply

Stock management: ongoing administration of stock to make sure that inventory ranges are maintained at adequate ranges to satisfy buyer demand with out overstocking

/cdn.vox-cdn.com/uploads/chorus_asset/file/25629525/2167038723.jpg)