Stock administration is the inspiration of any profitable retail enterprise. Inventory availability, avoiding overstock and correct monitoring aren’t simply operational duties—they immediately have an effect on money stream, buyer expertise and general effectivity. However even for seasoned enterprise homeowners, stock administration is usually a fixed problem.

The complexity solely grows as companies add extra areas or gross sales channels. Actual-time monitoring, clear processes and correct forecasting aren’t nice-to-haves—they’re non-negotiable for staying aggressive. With out the suitable techniques, even small missteps can result in costly errors or misplaced alternatives.

The hot button is figuring out what the widespread challenges are and utilizing options that scale with your online business.

Develop your retail enterprise.

Streamline stock, suppliers, groups and shops with Lightspeed’s all-in-one platform. From intuitive POS and inventory administration options to highly effective reporting, Lightspeed offers you the instruments it’s essential develop.

20 widespread stock administration challenges

Quickly altering buyer demand

Buyer demand isn’t static—it shifts quick. Stockouts imply missed gross sales, however overstock ties up money that could possibly be used elsewhere. Predicting developments and adjusting stock ranges shortly is the one strategy to keep forward.

Inaccurate information and evaluation

Dangerous information results in dangerous selections. Errors in stock information trigger over-ordering, understocking and wasted assets. Actual-time monitoring retains every thing correct so you’ll be able to plan with confidence.

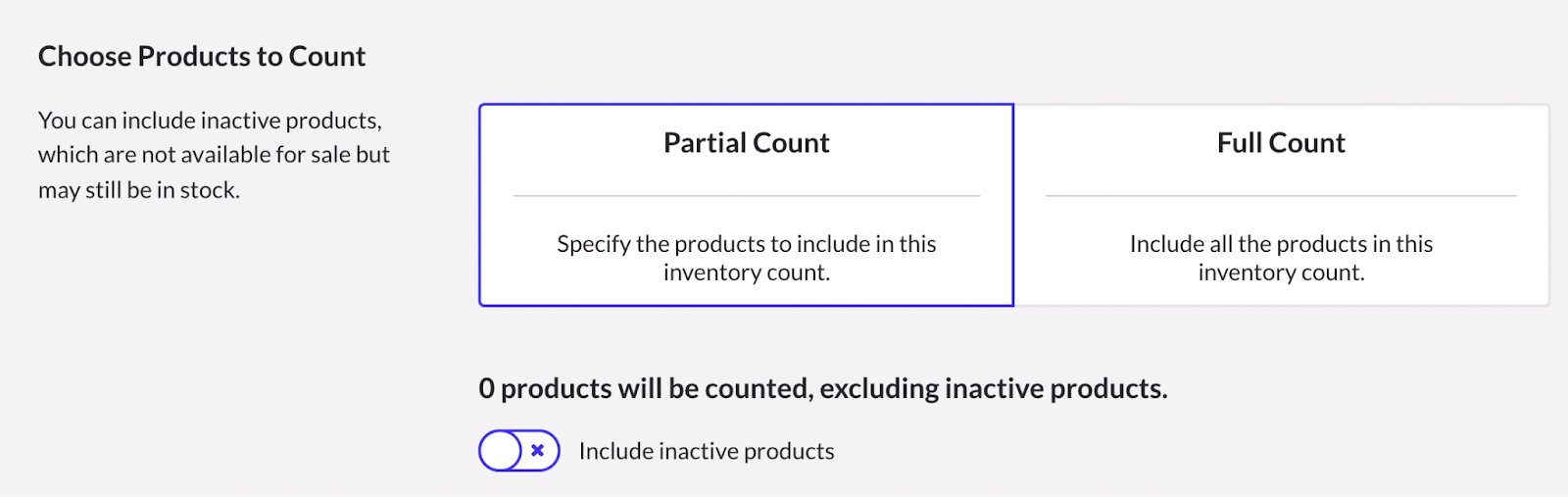

It’s additionally necessary to just remember to and your staff keep on high of bodily stock counts and audits. That approach, your stock ranges are at all times updated.

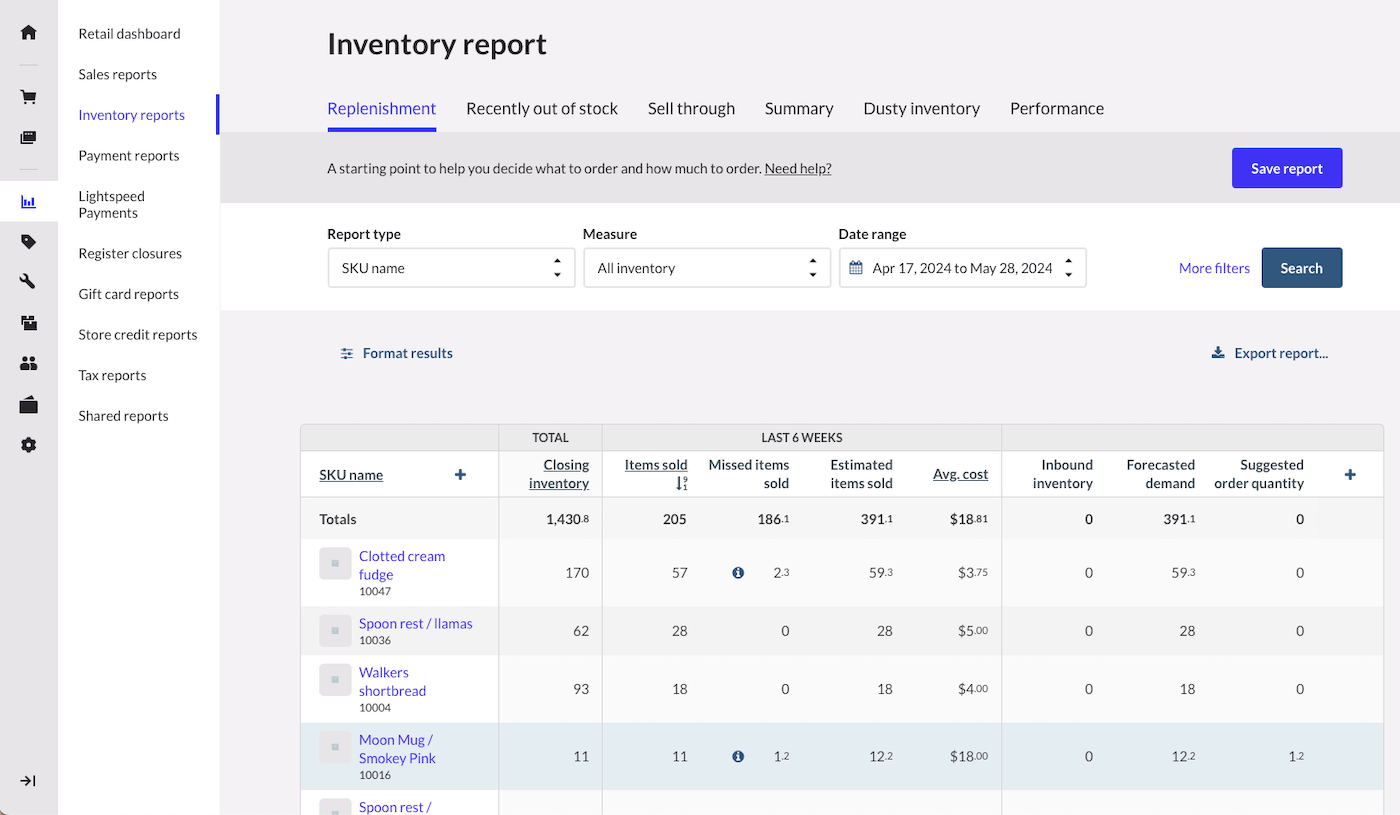

One software to think about is Lightspeed Scanner, which lets groups depend gadgets by merely scanning barcodes into the app. Scanner turns your cellular gadget into a strong inventory counting software that streamlines bodily counts and permits a number of staff to work concurrently.

Reordering delays

Late reorders throw every thing off—empty cabinets, misplaced gross sales and pissed off clients. Counting on guide monitoring usually means missed reorder factors.

The answer? Use a retail administration answer that allows you to set security inventory ranges and reorder factors so merchandise may be replenished earlier than they run out.

Lightspeed Retail has built-in reorder factors and restock ranges that routinely populate orders when inventory is low, saving you time and guaranteeing you by no means run out of bestsellers. By setting reorder factors for every product and outlet, you’ll be able to proactively restock earlier than operating low, maintaining gross sales flowing easily.

Poor manufacturing planning

When manufacturing doesn’t match gross sales, the outcomes are messy. Overproduction clogs up storage, whereas underproduction leaves orders unfulfilled.

One strategy to fight that is by aligning manufacturing schedules with real-time stock information to verify provide matches demand. Doing so prevents expensive inventory imbalances and ensures merchandise can be found when clients want them—maintaining gross sales regular and operations environment friendly.

Stock defects and waste

Faulty merchandise don’t simply value cash—they waste invaluable area and assets. Batch and serial quantity monitoring makes it easy to pinpoint and isolate points earlier than they spiral.

If defects stem from vendor or provider points, having a structured high quality management course of is vital. Usually inspecting incoming shipments, setting clear high quality requirements with suppliers, and leveraging vendor efficiency experiences may help establish recurring points.

One other tip? Negotiating higher phrases with distributors—like refunds for faulty items or improved packaging—can even decrease losses.

Ordering errors

Handbook ordering usually results in errors—an excessive amount of, too little or the flawed gadgets altogether. Automating the method ensures accuracy, so stock stays on observe with out guesswork.

You may sidestep this stock misstep by automating buy orders in your online business. Select an answer that retains your POs and stock in sync.

Lightspeed NuORDER is a good instance of a platform that automates provider data and retains your product information correct. It syncs 1000’s of merchandise along with your POS, permitting retailers to import pre-loaded particulars—like UPCs, MSRP, descriptions and pictures—immediately from suppliers. This eliminates guide entry errors and accelerates buy order creation.

Lisa Bobb, proprietor of Squash Blossom Boutique makes use of Lightspeed NuORDER to streamline her buy order workflows. Doing so permits her to create POs 80% sooner.

“It used to take me about 25 minutes to do my PO information entry,” she says. “Now, I can get it executed inside about 5 minutes.”

Capital tied up in unused stock

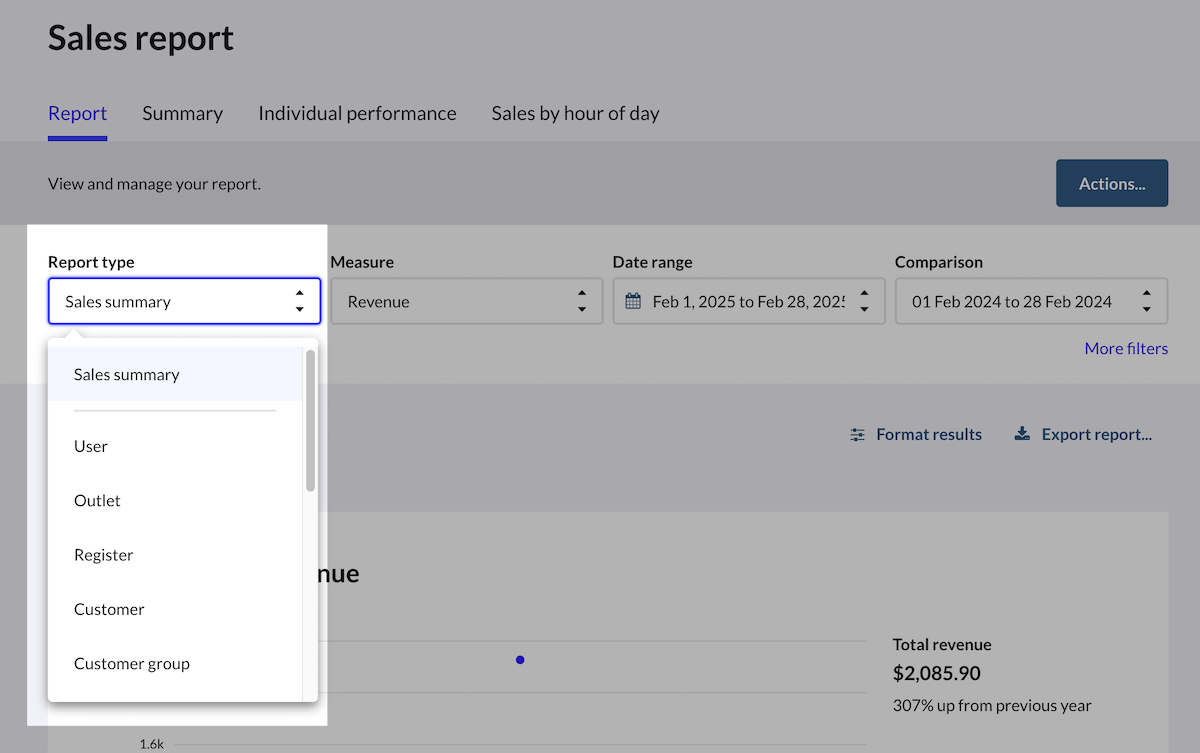

Extra inventory ties up money your online business may use for development. Figuring out slow-moving merchandise helps filter what’s not promoting and frees up working capital for what’s. You are able to do this by producing product efficiency experiences that make clear gross sales and stock turnover.

For greatest outcomes, select stock monitoring software program that allows you to filter information by product class, model, provider and different parameters so you’ll be able to pinpoint slow-moving stock, make knowledgeable markdown selections and optimize reordering.

Overstocking

An excessive amount of stock doesn’t simply take up area—it will increase storage prices and dangers obsolescence. Balancing inventory with optimization instruments prevents overstock whereas maintaining cabinets prepared for gross sales.

There are a number of techniques that can assist you keep away from surplus inventory, together with:

Setting reorder factors and restock ranges

Monitoring gross sales developments

Implementing just-in-time (JIT) stock

Utilizing demand forecasting

Working strategic promotions

Optimizing provider relationships

Improper stock storage

Disorganized storage damages merchandise and slows down success. Poor practices additionally improve shrinkage.

That’s why it pays to have a transparent system for organizing stock. It ensures gadgets are saved correctly and simple to entry.

Consider your stockroom and product storage practices. From there, implement standardized labeling, logical shelving preparations, and clear stock zones to streamline operations and scale back errors.

For instance, a clothes retailer would possibly manage stock by measurement and colour, with clear signage and bin labels, guaranteeing workers can shortly discover gadgets. A grocery retailer may use a first-in, first-out (FIFO) system by inserting newer inventory behind older gadgets to scale back waste and stop expired merchandise from being offered.

A number of inventory storage areas

Managing stock throughout a number of areas will get difficult quick. With out centralized visibility, it’s arduous to maintain issues operating easily. A unified system connects all areas so you’ll be able to observe every thing in a single place.

Professional tip: you need to use a cloud-based stock administration software program to handle all of your shops from one centralized platform. Go for a system that allows you to switch inventory and oversee a number of areas so you’ll be able to keep on high of stock throughout your complete operation.

Lack of transportation capability

When transportation is unreliable, shipments get delayed and provide chains collapse. Whereas stock instruments can’t clear up logistics on their very own, integrating them with transport administration ensures higher coordination.

Lack of warehouse area

Cluttered warehouses sluggish operations and create inefficiencies. Monitoring underperforming gadgets helps liberate area by clearing out what’s not transferring.

Think about implementing vertical storage options, optimizing shelving layouts, and utilizing clear labeling to maximise area effectivity.

One other step to take? Usually audit stock to establish slow-moving or out of date inventory in order that they’re not taking on area in your warehouse. You may run promotions or bundle offers to clear them out.

Moreover, reevaluating provider order portions can forestall overstocking and maintain storage areas organized.

Lack of consideration to fast-moving gadgets

Excessive-demand merchandise want fixed consideration—ignoring them means missed gross sales. Monitoring gross sales developments ensures you at all times know what’s flying off the cabinets and when to restock.

As talked about above, it’s greatest to arrange automated alerts for low inventory ranges so you’ll be able to reorder fast-moving gadgets earlier than they run out.

You also needs to usually evaluation gross sales experiences to establish peak demand durations and regulate buying accordingly.

Reliance on guide processes

Handbook stock administration is sluggish and riddled with errors. Automating repetitive duties speeds issues up, reduces errors and lets groups concentrate on what issues most.

Begin by digitizing stock monitoring with barcode scanners or RFID techniques. These options decrease human error and streamline inventory counts. From there, automate buy orders based mostly on preset reorder factors ensures you by no means run out of important merchandise.

Lastly, integrating stock administration with gross sales and success techniques offers real-time inventory updates, decreasing discrepancies.

Lack of required packaging

Working out of packaging supplies whenever you want them delays shipments and frustrates clients. Monitoring packaging alongside merchandise ensures you’re at all times ready to satisfy orders.

Monitor packaging stock identical to product inventory by setting reorder factors for important supplies resembling bins, tape, and protecting fillers. Streamline ordering by working with dependable suppliers and negotiating bulk reductions to keep away from last-minute shortages. Think about sustainable packaging choices which can be cost-effective and available. Usually reviewing order quantity developments helps anticipate packaging wants, guaranteeing you may have the suitable supplies available to maintain success operating easily and clients glad.

Delaying stock counting

Pushing aside stock counts results in discrepancies and misplaced management. Common, real-time counts maintain every thing correct with out the necessity for catch-up audits.

Professional tip: implement cycle counting, the place small sections of stock are counted usually as an alternative of conducting a full depend suddenly. Assign accountability to staff members to make sure accountability and consistency.

Relying in your retailer, it’s possible you’ll wish to think about scheduling counts throughout slower enterprise hours to keep away from disruptions.

Pausing warehouse operations

Stopping every thing to manually test stock disrupts workflows and kills productiveness. The answer? Steady monitoring eliminates the necessity for pauses so operations don’t grind to a halt.

Other than rolling stock counts to maintain operations operating easily whereas sustaining accuracy, use real-time monitoring techniques that replace inventory ranges as gadgets transfer out and in.

Additionally, practice workers to conduct spot checks throughout common shifts as an alternative of halting workflows for large-scale audits. Streamlining stock administration with clear processes ensures that inventory stays correct with out disrupting order success, maintaining enterprise operations environment friendly and uninterrupted.

Lack of information transparency

When stock information isn’t accessible, decision-making suffers. Actual-time reporting retains every thing seen, giving groups the data they should act shortly.

With out clear visibility, inventory discrepancies go unnoticed, resulting in expensive errors. A centralized stock system ensures that each one staff members—from warehouse workers to administration—have entry to the identical up-to-date data. Setting person permissions permits the suitable individuals to trace inventory ranges, monitor gross sales developments, and make knowledgeable buying selections. Usually reviewing stock experiences helps establish patterns, forestall stockouts, and optimize storage, guaranteeing that companies keep agile and conscious of demand.

Poor integration with different software program and techniques

Disconnected instruments create inefficiencies and bottlenecks. Seamless integration between stock techniques and different platforms retains data flowing easily throughout the enterprise.

When techniques don’t talk, stock discrepancies, delayed order success and information silos turn into inevitable. Selecting software program that integrates with accounting, ecommerce and provide chain administration instruments ensures correct reporting and clean operations. Automated information syncing reduces guide enter errors and retains inventory ranges up to date in actual time.

What’s extra, usually auditing system connections and workflows helps establish gaps, guaranteeing that each a part of the enterprise operates effectively with out pointless delays or miscommunication.

Lack of provide chain agility

Inflexible provide chains can’t sustain with sudden modifications in demand or disruptions. Versatile stock instruments assist companies adapt shortly, avoiding downtime and missed alternatives.

When provide chains lack flexibility, inventory shortages and overages turn into expensive issues. Constructing relationships with a number of suppliers offers backup choices in case of delays. Preserving security inventory for high-demand gadgets reduces the danger of operating out throughout disruptions. Demand forecasting, based mostly on real-time gross sales information, helps companies anticipate shifts and regulate orders accordingly. Periodically reviewing provider efficiency and renegotiating phrases ensures that sourcing methods stay agile and conscious of market situations.

Backside line

Stock administration points—like inaccurate monitoring, overstocking, or poor demand forecasting—can disrupt operations and stall development. The appropriate instruments make all of the distinction. Actual-time visibility, streamlined multi-location oversight, and automation are key to fixing these challenges. A POS system constructed for stock administration retains every thing operating easily whereas providing you with extra time to concentrate on rising your online business.

With forecasting instruments, centralized information, and automation, managing inventory not looks like guesswork. You may forestall money stream issues, lower down on waste, and maintain clients pleased with dependable inventory availability. It’s about higher effectivity, higher margins, and higher outcomes throughout each location.

Watch a demo to see how the suitable POS system can take your stock administration to the subsequent stage.

FAQs

What integrations does Lightspeed POS supply for stock administration?

POS techniques are designed to work seamlessly with instruments like accounting software program, ERP platforms and ecommerce options. These integrations join your techniques, slicing down on guide information entry and decreasing errors. For stock administration, widespread integrations embody provider catalogs, delivery instruments and analytics platforms—maintaining every thing streamlined and in sync.

How does Lightspeed POS enhance information accuracy in stock administration?

Correct stock information will depend on two issues: real-time monitoring and centralized updates. POS techniques deal with each by automating inventory counts, syncing gross sales throughout all channels and creating audit trails for each transaction. The consequence? Clear, dependable information that make it simpler to forecast demand and keep away from expensive errors.

Can Lightspeed POS deal with multi-location stock administration?

Managing stock throughout a number of areas doesn’t must be difficult. A powerful POS system tracks inventory in real-time, regardless of what number of shops or warehouses you’re operating. With a centralized dashboard, you’ll be able to monitor stock ranges, transfer gadgets between areas and set reorder factors—all whereas maintaining every thing correct and environment friendly.